2023/06/20 – House4Hack Meetup: Skullkey and Philip Modify the SpeedsterDen Wisel Design

by Blog Bot

At this week’s House4Hack Meetup, two of our members, Skullkey and Philip, were hard at work modifying the SpeedsterDen Wisel’s design. With their combined skills in aviation and engineering, they decided to modify the airfoil thickness of the design by 7.5%. To bring their vision to life, they utilized the CNC foam cutter, cutting out the foam cores to make the perfect wings.

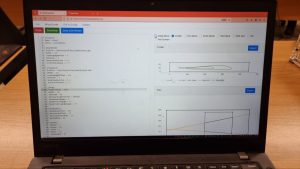

Their first step was to design the modified SpeedsterDen Wisel wings. They used HotWing, an open-source software for designing airfoils and wings.

Design using hotwingOnce they finished the design, they moved onto the cutting stage.

To cut the foam cores, Skullkey and Philip used Pronterface to feed the GCode to the foam cutter.

Pronterface to feed the gcode to the foam cutter

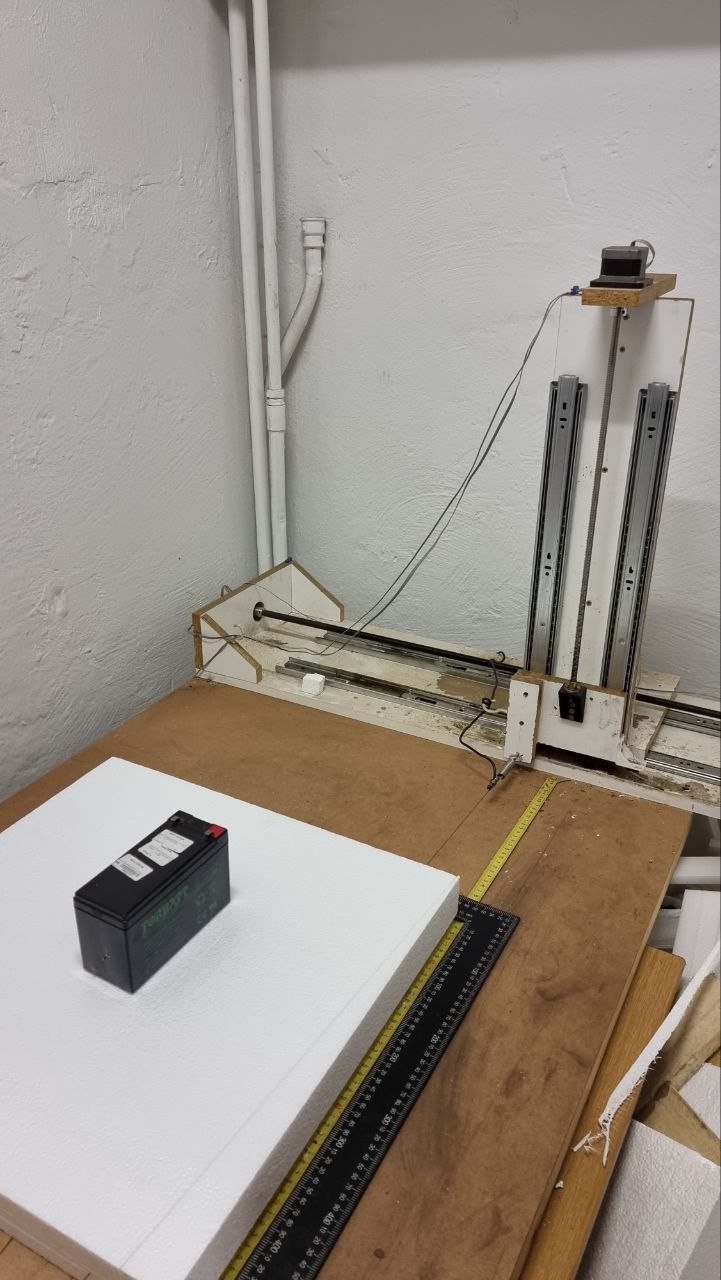

The foam cutter was in action, carefully and precisely cutting the modified SpeedsterDen Wisel wings.

Foam cutter in action

After some time and hard work, the foam cores were finally cut, and the end product was fantastic.

The final wing – left and right – fits perfectly.

Final wing, left and right, fits perfectly

From this point, all that’s left is to build the modified SpeedsterDen Wisel, which they plan to do next week. We are excited to see what the final product looks like and can’t wait to see how it performs!

At House4Hack, it’s all about learning, experimenting, and having fun. It’s inspiring to see members like Skullkey and Philip work together to design and build something unique. We are proud of our community of makers at House4Hack and can’t wait to see what is created in the next Meetup. Stay tuned!

At this week’s House4Hack Meetup, two of our members, Skullkey and Philip, were hard at work modifying the SpeedsterDen Wisel’s design. With their combined skills in aviation and engineering, they decided to modify the airfoil thickness of the design by 7.5%. To bring their vision to life, they utilized the CNC foam cutter, cutting out…

Get involved

Visit us on a Tuesday:

- Join us at 4 Burger Ave, Lyttleton Manor, Centurion every Tuesday evening from 18.00 till late (bring a project to work on or beer)

Telegram Group:

- Send a message to Schalk on Telegram to add you to the group - currently >100 users, relevant conversations for makers

IRL:

- Schalk 082 777 7098

After hours only, please rather send telegram message - Toby

http://tobykurien.com

- Not active at the moment, if you are interested in presenting a course, please let Schalk know